x

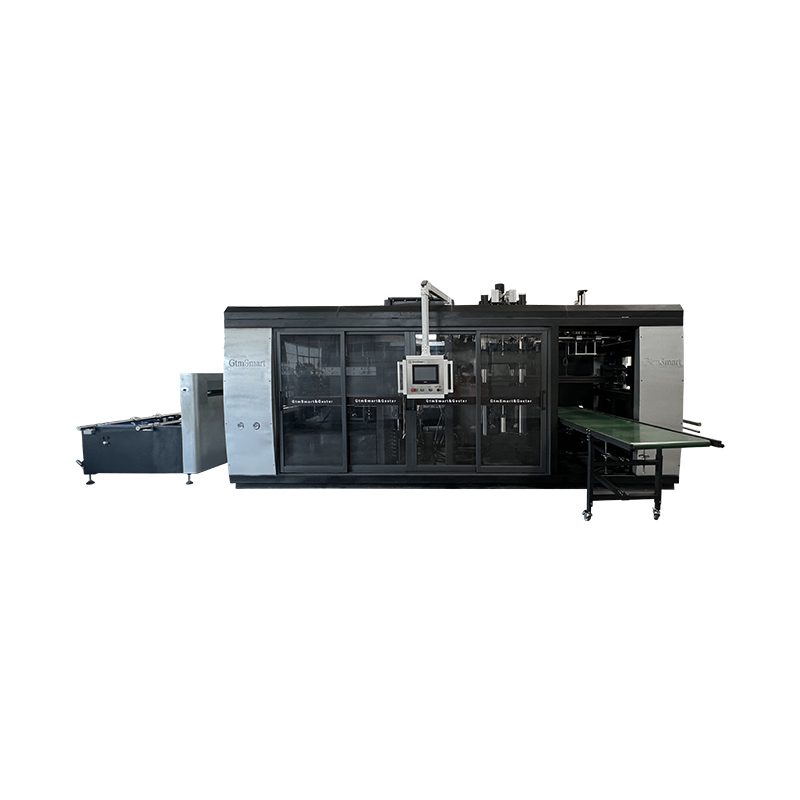

Product Introduction

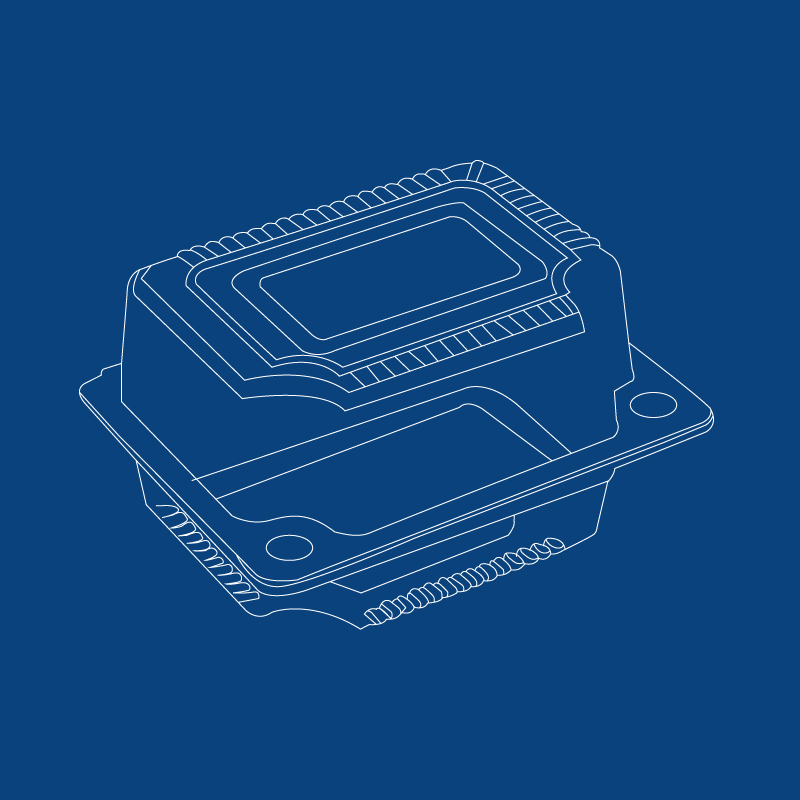

Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) with thermoplastic sheets, such as PP, APET, PS, PVC, EPS, OPS, PEEK, PLA, CPET, etc.

Feature

● More efficient energy use and material utilization.

● The heating station uses high-efficiency ceramic heating elements.

● The upper and lower tables of the forming station are equipped with independent servo drives.

● Single Station Automatic Thermoforming machine has a pre-blowing function to make the product molding more in place.

Key Specification

| Model |

HEY03-6040 |

HEY03-6850 |

HEY03-7561 |

| Max.Forming Area (mm2) |

600x400 |

680x500 |

750x610 |

| Sheet Width (mm) | 350-720 | ||

| Sheet Thickness (mm) | 0.2-1.5 | ||

| Max. Dia. Of Sheet Roll (mm) | 800 | ||

| Forming Mould Stroke(mm) | Upper Mould 150, Down Mould 150 | ||

| Power Consumption | 60-70KW/H | ||

| Forming Mould Width (mm) | 350-680 | ||

| Max. Formed Depth (mm) | 100 | ||

| Dry Speed (cycle/min) | Max 30 | ||

| Product Cooling Method | By Water Cooling | ||

| Vacuum Pump | UniverstarXD100 | ||

| Power Supply | 3 phase 4 line 380V50Hz | ||

| Max. Heating Power | 121.6 | ||

Applications

Send your message to us:

Write your message here and send it to us

Products Recommended

More +-

Model: HEY01

Model: HEY01PLC Pressure Thermoforming Machine With Three Stations HEY01

PLC Pressure Thermoforming Machine With Three Stations HEY01 Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit cont... -

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, ... -

Model:

Model:Plastic Cup Thermoforming Machine

Cup Thermoforming Machine Application The whole Plastic Cup Thermoforming Machine Mainly for the production of variety plastic containers ( jelly cups, drink cups, disposable cup, package co... -

Model: HEY12

Model: HEY12Full Servo Plastic Cup Making Machine HEY12

Full Servo Plastic Cup Making Machine cup making machine Application The cup making machine is Mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers, ... -

Model: HEY06

Model: HEY06Three Stations Negative Pressure Forming Machine HEY06

Three Stations Negative Pressure Forming Machine HEY06 Application This Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package ... -

Model: HEY05B

Model: HEY05BServo Vacuum Forming Machine HEY05B

Automatic Vacuum Forming Machine Specifications Model HEY05B Working Station Forming, Stacking Applicable Material PS, PET, PVC, ABS Max. Forming Area (mm2) 1350*760 Min. Formi... -

Model: HEY14

Model: HEY14Rim Roller HEY14

Features 1.Integrated design, optical fiber cup, high efficiency, low energy consumption. 2.Give consideration to two functions of curling and counting. 3.Edge screw is made of copper, which is mor...