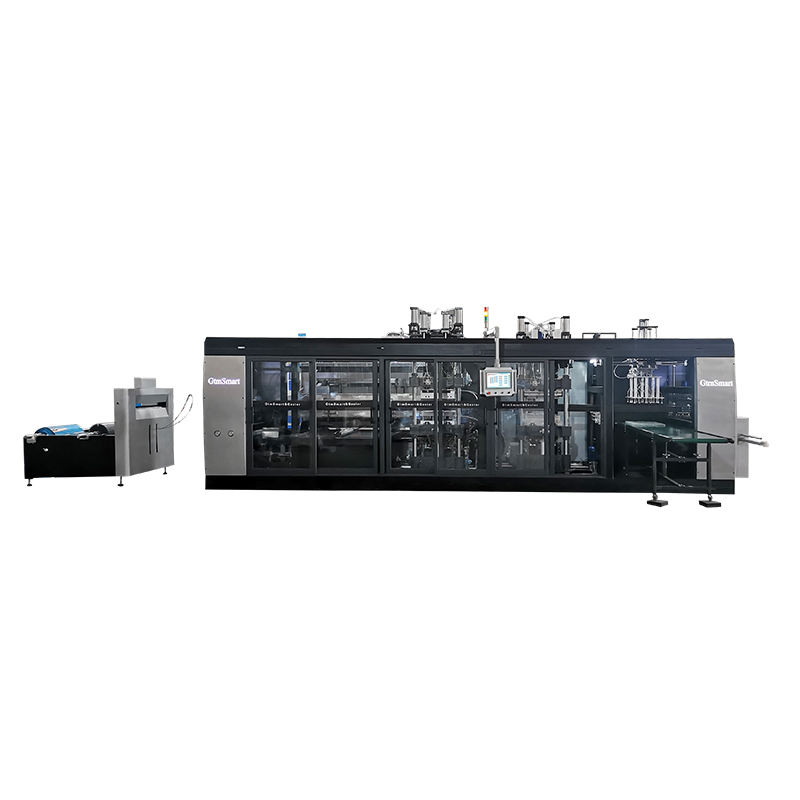

Product Introduction

This One Station Thermoforming disposable food container making machine is a trim-in-place type thermoforming machine which takes advantage of mould with rules steel knife for performing forming and cutting in the same station. and the second and the third cut-station are available for performing fuction of post-trim and hole-punch.

Thermoforming machinery is perfect for making part of PP PET PS etc and completely automatically produces disposable rectangular or square or round shaped roll-edged containers and trays with forming, trimming, and stacking conveying on one operation cycle.

Feature

1.Thermofomring machinery Use Steel-Rule-knife for performing forming and cutting in the same station.

2.This thermoforming machine automatic stacking ,counting unit and conveying system

3.Trim-in-place for parts with rolled edge (turn-down lip)

4.Technology of trim-in-place brings a neat and identical trimming(cutting)

5.Plug assistant for deep forming of draw

6.Floating knife and free knife are available for post-trimming film with high shrinkage rate.

7.Extra Contact Heat plate for Minimizing power consumption is available.

Key Specification

| Model |

HEY03-6040 |

HEY03-6850 |

HEY03-7561 |

| Max.Forming Area (mm2) |

600x400 |

680x500 |

750x610 |

| Sheet Width (mm) | 350-720 | ||

| Sheet Thickness (mm) | 0.2-1.5 | ||

| Max. Dia. Of Sheet Roll (mm) | 800 | ||

| Forming Mould Stroke(mm) | Upper Mould 150, Down Mould 150 | ||

| Power Consumption | 60-70KW/H | ||

| Forming Mould Width (mm) | 350-680 | ||

| Max. Formed Depth (mm) | 100 | ||

| Dry Speed (cycle/min) | Max 30 | ||

| Product Cooling Method | By Water Cooling | ||

| Vacuum Pump | UniverstarXD100 | ||

| Power Supply | 3 phase 4 line 380V50Hz | ||

| Max. Heating Power | 121.6 | ||

Send your message to us:

Products Recommended

More +-

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, ... -

Model: HEY01

Model: HEY01High Speed Automatic Pressure PET Thermoforming Machine

Product Introduction This High Speed Automatic Pressure PET Thermoforming Machine adopts the method of laminating heating, adopts the technology of moving film punching, no secondary pollution, hig... -

Model: HEY01

Model: HEY01Three Station Fully Automatic Plastic Thermoforming Machine

Product Introduction Fully Automatic Thermoforming Machine: Integrated heating, forming, punching and stacking stations. Thermoformer use high-efficiency ceramic heating elements; laser knife ...