x

Lid Making Machine Introduction

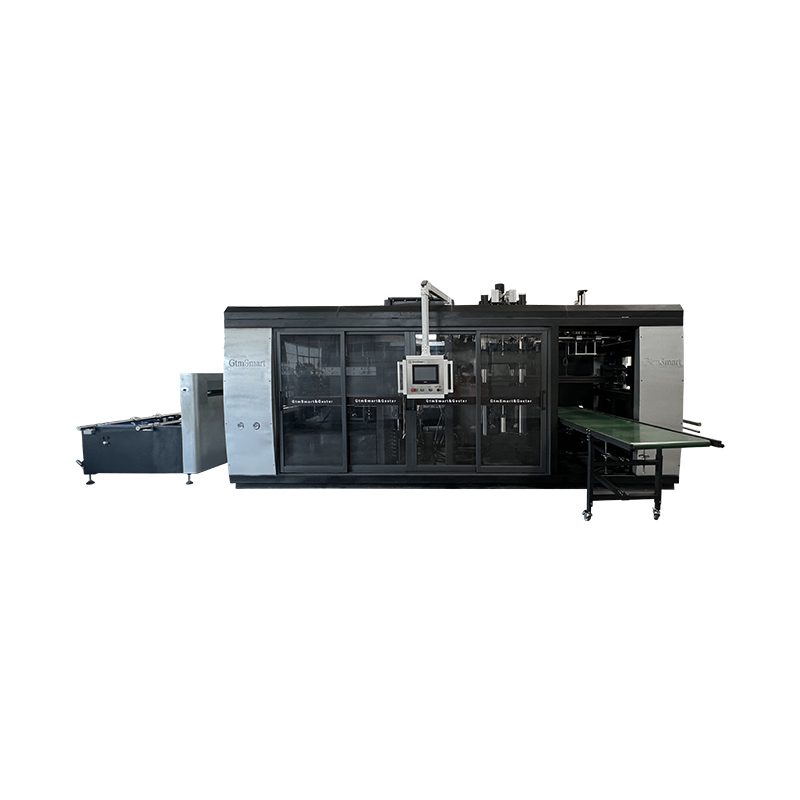

The lid making machine includes forming, punching & cutting, automatic process operation, advanced technology, safe and easy operation, to avoid the labor consumption caused by manual punching in the past and the pollution caused by the contact of employees during work, to ensure the quality requirements in the production process of the product, the equipment adopts the plate heating production power consumption is small, the appearance covers a small area, economical and practical, widely used in food, medicine, hardware and other industries production.

Lid Making Machine Features

- Plastic lid making machine: through the organic combination of programmable controller (PLC), human-machine interface, encoder, photoelectric system, etc., intelligent control is realized, and the operation is simple and intuitive.

- It adopts coaxial mechanical transmission mode, and the synchronization performance is reliable and stable.

- The automatic lifting feeding system is safe and labor-saving, the radial upper and lower preheating device has stable temperature control, uniform heating, intelligent and reliable servo traction, the punching and punching knives are durable and burr-free, the mold is easy to replace, and the host adopts frequency conversion speed regulation and runs smoothly.

- The heating method adopts matrix-shaped heating tile infrared radiation heating, and the high-precision temperature control system is used for temperature control.

- The traction adopts full-tooth chain fixed-point servo traction, and the chain guide rail is equipped with a cooling system for heat-treated aluminum profiles, with accurate stroke positioning and high service life.

- The plane connecting rod mechanism is used to transmit large force, small inertia, stable operation, equipped with servo system intelligent control, the laser tool used is small in size, low in cost, easy to adjust and replaced, and the finished product is smooth and burr-free after pressing and cutting.

- This Cup Lid Thermoforming Machine is also equipped with a powerful servo automatic stacking system, which can greatly save labor costs for the majority of users.

- The appearance of the whole machine is sprayed with plastic, and the appearance is beautiful and generous.

Technical Parameters

| Speed | 10-35 cycle/min;6~15 cavity/cycle |

| Capacity | 13500 pcs/hr(e.g. 15 cavities, 15 cycles/min) |

| Max. forming area | 470*340mm |

| Max. forming depth | 55mm |

| Traction | 60~350mm |

| Material | PP/PET/PVC (please inform us in advance if you will use this machine for PS material)

0.15-0.60mm(sheet roll holdingscrew φ75mm) |

| Heating power | Top heater:26kw bottom heater:16kw |

| Main motor power | 2.2kw |

| Total power | ≈48kw |

| Air capacity | >0.6m³(self-prepared) pressure: 0.6-0.8Mpa |

| Mold cooling | 20℃, tap water recycling |

| Dimension | 6350×2400×1800mm(L*W*H) |

| Weight | 4245kg |

Applications

Send your message to us:

Write your message here and send it to us

Products Recommended

More +-

Model: HEY04A

Model: HEY04AAutomatic Lid Thermoforming Machine HEY04A

-

Model: HEY12

Model: HEY12Biodegradable PLA Disposable Plastic Cup Making Machine

PLA Biodegradable Disposable Plastic Cup Making Machine Application Biodegradable cup making machine mainly for the production of variety plastic containers ( jelly cups, drink cups, package conta... -

Model: HEY01

Model: HEY01PLC Pressure Thermoforming Machine With Three Stations HEY01

PLC Pressure Thermoforming Machine With Three Stations HEY01 Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit cont... -

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, ... -

Model: HEY03

Model: HEY03Single Station Automatic Thermoforming machine HEY03

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc... -

Model: HEY05

Model: HEY05Plastic Vacuum Forming Machine HEY05

Vacuum Thermoforming Machine Description Vacuum forming, also known as thermoforming, vacuum pressure forming or vacuum molding, is a procedure in which a sheet of heated plastic material is... -

Model: HEY06

Model: HEY06Three Stations Negative Pressure Forming Machine HEY06

Three Stations Negative Pressure Forming Machine HEY06 Application This Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package ... -

Model:

Model:Biodegradable PLA Lids

MOQ: 20GP PLA Biodegradable Factory direct sale Environmentally friendly Lids sold separately. Customizable Compostable PLA cup lids fits on 9, 12, 16, 20 and 24 oz cups. PLA bio-plastic made fro... -

Model:

Model:PLA Corn Starch Biodegradable Compostable Disposable Cups

Product parameters Product Name biodegradable cup Capacity 8oz/9oz/10oz/12oz/24oz Materials PLA Color Red and white, Clear MOQ 5000 psc Feature Eco-Friendly Usage Cold drink/ Coffee/...