Hot-selling Tilt-Mold Thermoforming Machines - Three Stations Negative Pressure Forming Machine HEY06 – GTMSMART

Hot-selling Tilt-Mold Thermoforming Machines - Three Stations Negative Pressure Forming Machine HEY06 – GTMSMART Detail:

Application

Automatic Vacuum Forming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets.

Vacuum Forming Machine Features

1.Mechanical, pneumatic, electrical integration. Each action program is controlled by PLC. Touching screen operation is simple and convenient.

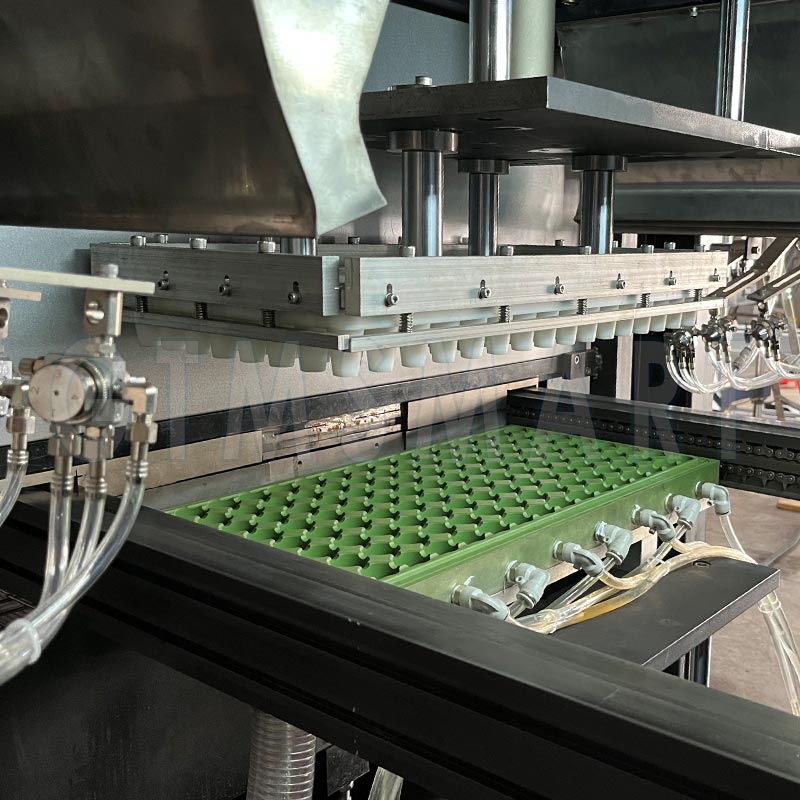

2.Vacuum Forming In-mould Cutting.

3.Up and down moulds forming type.

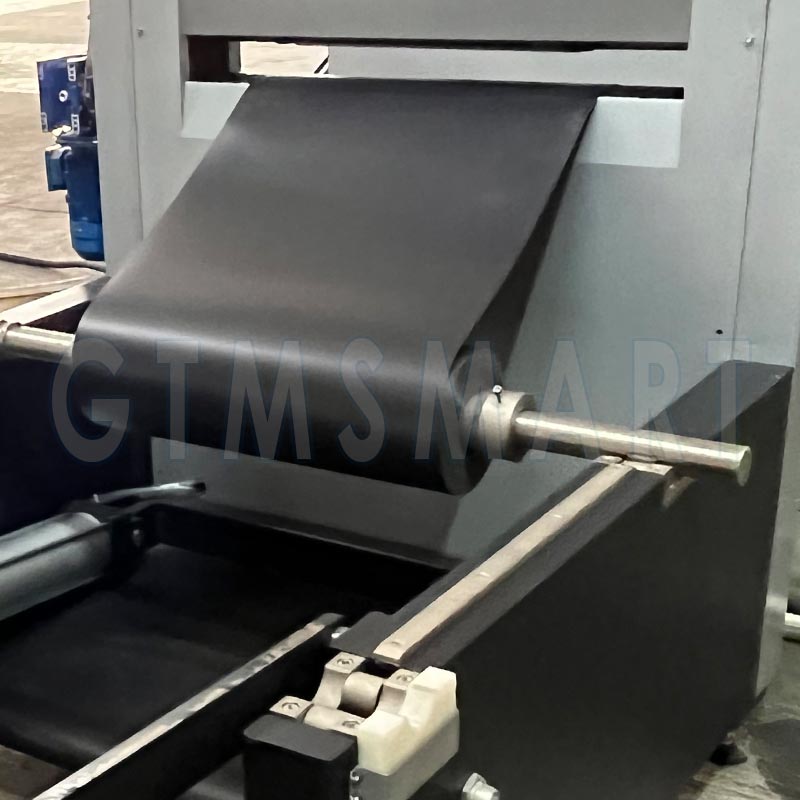

4.Servo feeding, length step less adjusting, high speed accurately and stablity.

5.Blister Vacuum Forming Machine Up and down heater with two phases heating.

6.Electric heating furnace temperature control system adopts full computer intelligent automatic compensation control, partition control using digital input interface one by one, has the high precision fine-tuning, uniform temperature, heating up fast (only 3 minutes from 0-400 degrees), stability (not influenced by external voltage, temperature fluctuations no more than 1 degree), low energy consumption (energy saving about 15%), the furnace plate advantages for long life.

7.Forming and cutting station with open and close servo motor control, products with automatic tally output.

8.Products can be choosing by you to down stacking type,Or the manipulator is taken in the mold.

9.Plastic vacuum forming machine with product information and data memory function.

10.Feeding caterpillar width can be synchronization automatic or discretely electric adjusting.

11.Heater automatic shift out device.

12.Mechanical loading device, reduce workers labor strength.

Vacuum Forming Machine Technical Parameter

| Forming Area | 850x780mm |

| Max.Forming Depth | 150mm |

| Sheet thickness | 0.2-1.5mm |

| Work Efficiency | Max. 30 cycles/ Min |

| Air Pressure | 0.9mpa |

| Power Consumption | 50-70kw/h |

| Max. Sheet Width | 760mm |

| Suited Material | PP, PS, PET, PVC |

| Total Max. Power | 110 |

| Overall size(LxWxH)mm | 10040x2600x3200 |

| Total Weight (T) | 7 |

Product detail pictures:

Related Product Guide:

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Hot-selling Tilt-Mold Thermoforming Machines - Three Stations Negative Pressure Forming Machine HEY06 – GTMSMART , The product will supply to all over the world, such as: Porto , Czech , Manchester , Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

Send your message to us:

Products Recommended

More +-

Model:

Model:Factory For Paper Cup Machine High Speed - Biodegradable PLA Disposable Plastic Cup Making Machi...

Application Biodegradable cup making machine mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers, etc) with thermoplastic sheets, such as PP, P... -

Model:

Model:Hot Selling for Plastic Food Container Making Machine Price - Single Station Automatic Thermofor...

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) wit... -

Model:

Model:Good Quality Disposable Glass Making Machine - Supply OEM/ODM China Best Tray Plastic Containers...

Sticking to the principle of “Super High-quality, Satisfactory service” ,We are striving to generally be a very good business partner of you for Supply OEM/ODM China Best Tray Plastic C... -

Model:

Model:Factory best selling Thermoforming Machine Là Gì - Four Stations Large PP Plastic Thermoforming ...

Product Introduction Four Stations Large PP Plastic Thermoforming Machine is forming, cutting and stacking in one line. It is completely driven by servo motor, stable operation, low noise, high eff... -

Model:

Model:Factory directly supply Plastic Dish Making Machine - PLC Pressure Thermoforming Machine With Th...

Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) with thermopla... -

Model:

Model:China Supplier Paper Cup Making Machine For Sale - Biodegradable PLA Disposable Plastic Cup Maki...

Application Biodegradable cup making machine mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers, etc) with thermoplastic sheets, such as PP, P...