x

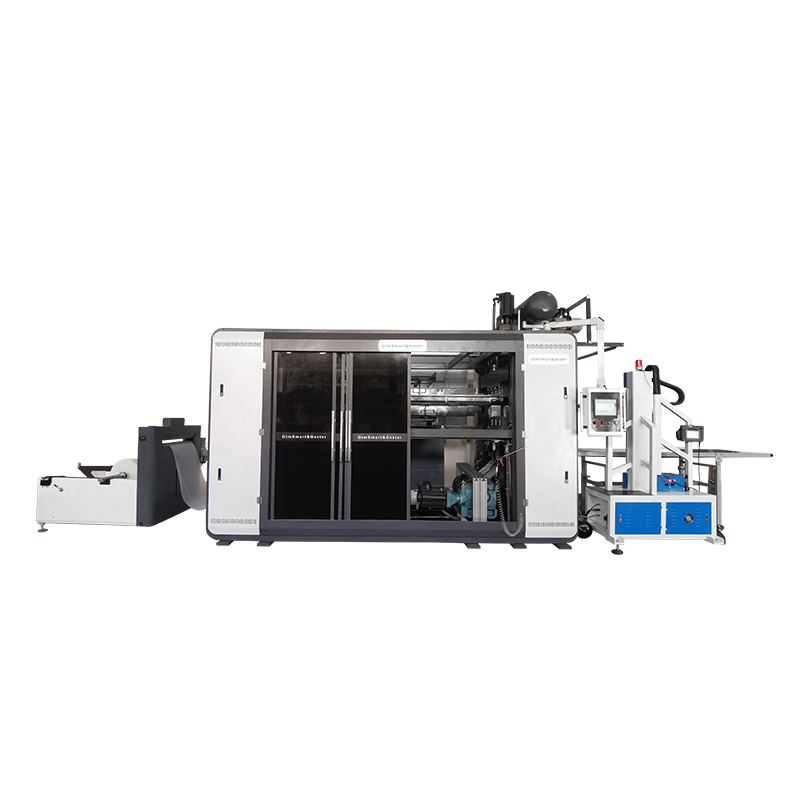

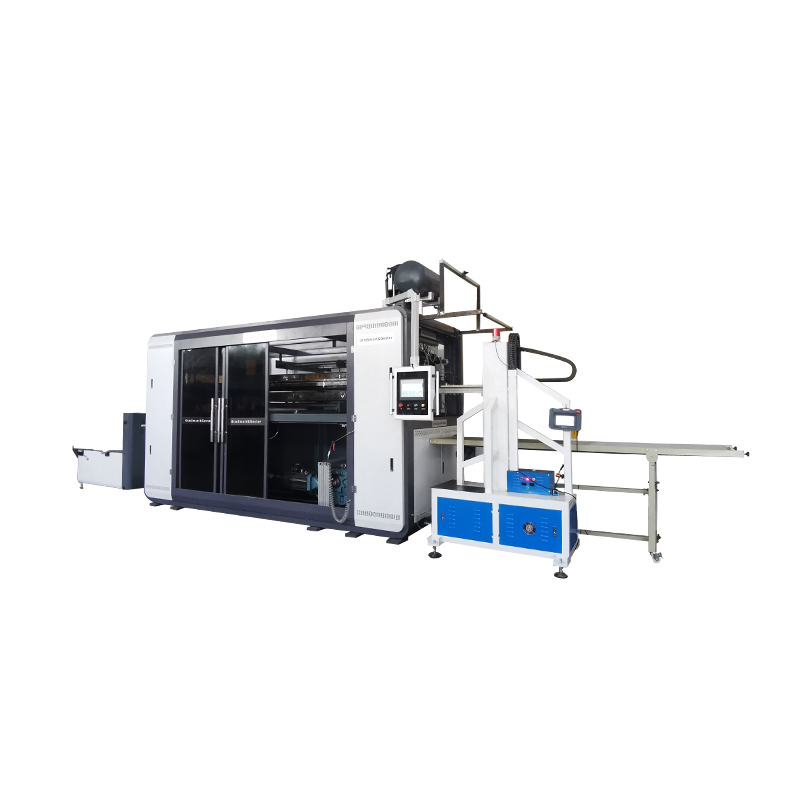

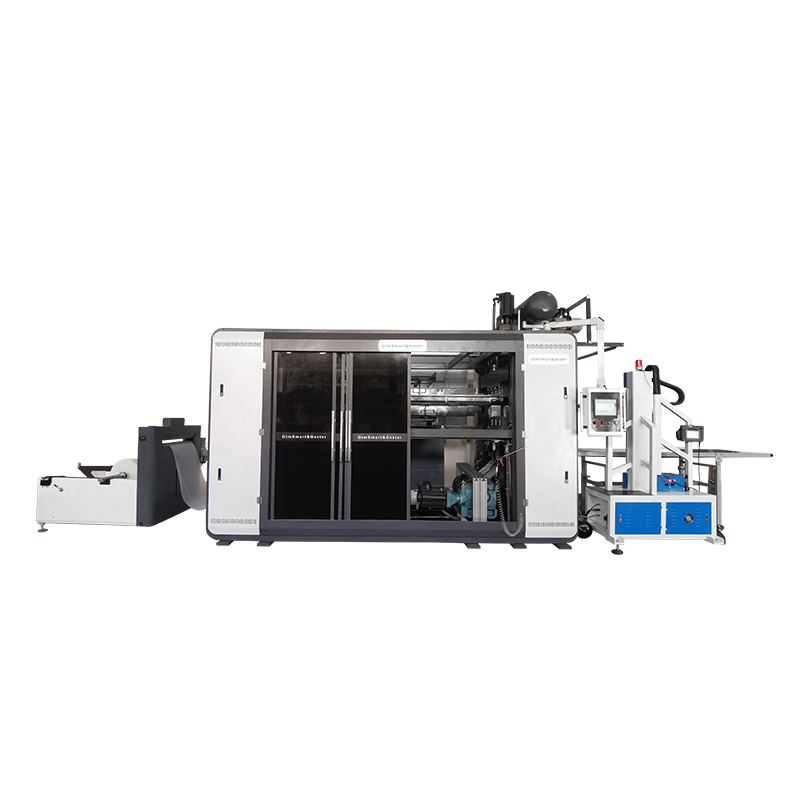

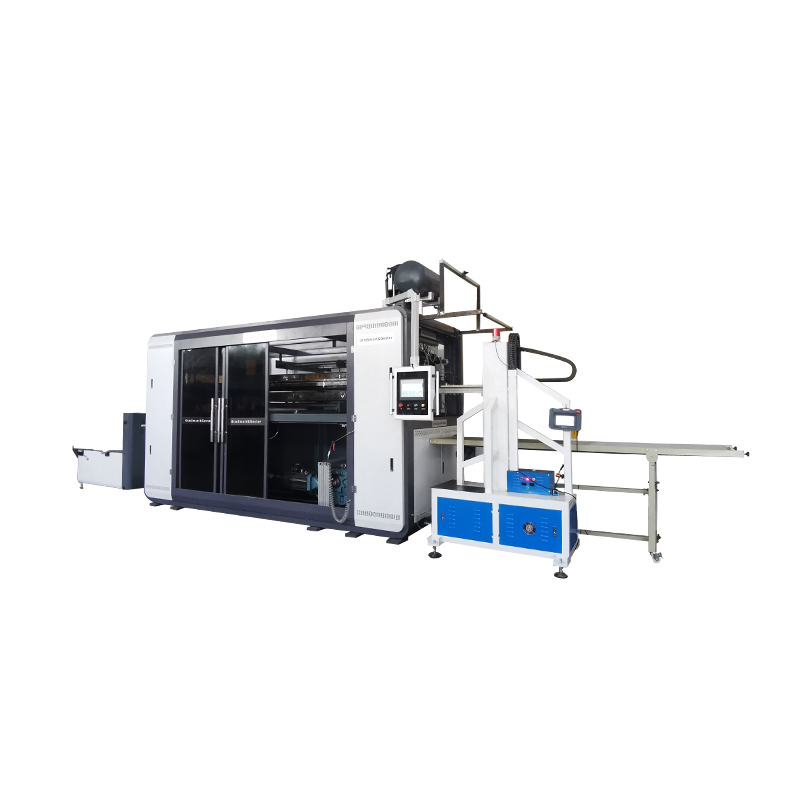

High reputation Cup Manufacturing Machine - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART

Model:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for

Automatic Paper Cup Machine Price

, Chai Ke Disposal Banane Ki Machine

, Thermoforming Machine For Sale In China

, We honor our core principal of Honesty in business, priority in service and will do our best to offer our customers with high quality products and excellent service.

High reputation Cup Manufacturing Machine - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART Detail:

Product detail pictures:

Related Product Guide:

Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for High reputation Cup Manufacturing Machine - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART , The product will supply to all over the world, such as: Armenia , Russia , Seychelles , Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

High reputation Cup Manufacturing Machine - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART Detail:

cup making machine Application

The cup making machine is Mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers, etc) with thermoplastic sheets, such as PP, PET, PE, PS, HIPS, PLA,etc.

Cup Making Machine Technical Specifications

| Model |

HEY12-6835 |

HEY12-7542 |

HEY12-8556 |

| Forming Area |

680*350mm |

750*420 mm |

850*560 mm |

| Sheet Width |

<680 mm |

<750 mm |

<850 mm |

| Max. Forming Depth |

<180 mm |

<220 mm |

<180 mm |

| Heating Rated Power |

130kw |

140kw |

150kw |

| Dimension |

5200*2000*2800mm |

5400*2000*2800mm |

5500*2000*2800mm |

| Machine Total Weight |

7T |

8T |

9T |

| Applicable Raw Material | PP, PS, PET, HIPS, PE, PLA | ||

| Sheet Thickness | 0.2-3.0 mm | ||

| Work Frequency | <35 | ||

| Motor Power | 15kw | ||

| Power Supply | Three Phase 380V/50HZ | ||

| Pressure Supply | 0.6-0.8 Mpa | ||

| Max.air Consumption | 3.8 | ||

| Water Consumption | 20M3/h | ||

| Control System | PLC Delta | ||

Supply Sheet Rack

| Feeding Reducer with Motor | Worm Gear Reducer (Supror) |

| Pneumatic Pressure | AirTAC Cylinder SC63×25=2PSC |

| Pneumatic Feeding Sheet | AirTAC Cylinder SC100×150=2PSC |

Electric Control

| Human-computer Interface | Delta |

| PLC | Delta |

| Servo Stretching Motor | Delta 11KW servo driver+servo motor |

| Servo Folding Motor | Delta 15KW servo driver+servo motor |

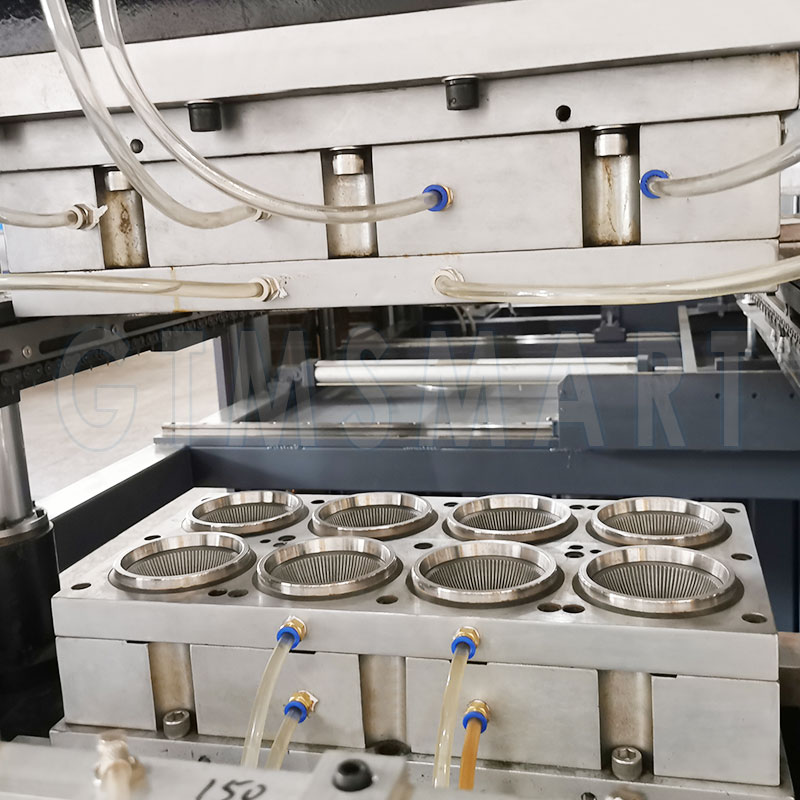

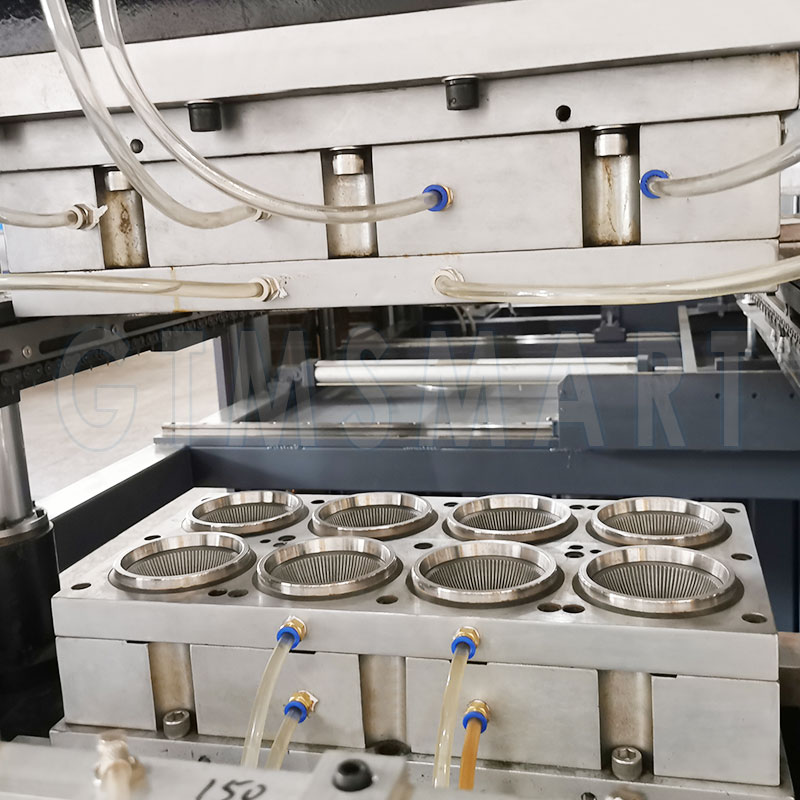

Forming Station

- Standard square tube frame with 100*100, mould is casted steel and upper mould is fixed by nut.

- Opening and closing mould driven by eccentric gear connecting rod.Driving power by 15KW (Japan Yaskawa) servo motor, American KALK Reducer,main axis use HRB bearings.

- Plastic Cup Thermoforming Machine Main pneumatic component use SMC(Japan) magnetic.

- Sheet feeding device with planetary gear reducer motor, 4.4KW Siemens servo controller.

- Stretching device uses 11KW Siemens servo.

- Lubrication device is fully automatic.

- Caterpillars adopt fully enclosed structure, with cooling device and can manually adjust sheet width.

- Heating system uses China ceramic far-infrared heaters, stainless steel upper and down heating furnace, upper heater with 12 pcs heating pads vertically and 8 pcs heating pads horizontally , down heater with 11 pcs heating pads vertically and 8 pcs heating pads horizontally.(specification of heating pad is 85mm*245mm);Electric furnace push-out system uses 0.55KW worm gear reducer and ball screw, which is more stable and also protect the heater pads.

- Cup Thermoforming Machine Air filtration uses triplet, blowing cup can adjust airflow.

- Folding mould is consist of fixed upper plate、flexible mid plate and 4 pillars with surface hard chrome plating 45#.

- Eccentric is the construction of connecting rod fold mould, with running range ≤ 240mm.

- Electric heating furnace could be moved horizontally and vertically freely by guide-rail from Hiwin Taiwan.

- Top cups is controlled by AirTAC (Taiwan) cylinder.

Waste Edge Winding Device

- On-line winding

- Reducer with 0.75KW motor (1 pc)

Product detail pictures:

Related Product Guide:

Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for High reputation Cup Manufacturing Machine - Full Servo Plastic Cup Making Machine HEY12 – GTMSMART , The product will supply to all over the world, such as: Armenia , Russia , Seychelles , Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

By Irene

from Senegal

- 2017.12.09 14:01

By Irene

from Senegal

- 2017.12.09 14:01

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

By Helen

from Nepal

- 2017.12.02 14:11

By Helen

from Nepal

- 2017.12.02 14:11

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

Send your message to us:

Write your message here and send it to us

Products Recommended

More +-

Model:

Model:High definition Biodegradable Pla Disposable Plastic Coffee Cup Making Machine - Supply OEM/ODM ...

Sticking to the principle of “Super High-quality, Satisfactory service” ,We are striving to generally be a very good business partner of you for Supply OEM/ODM China Best Tray Plastic C... -

Model:

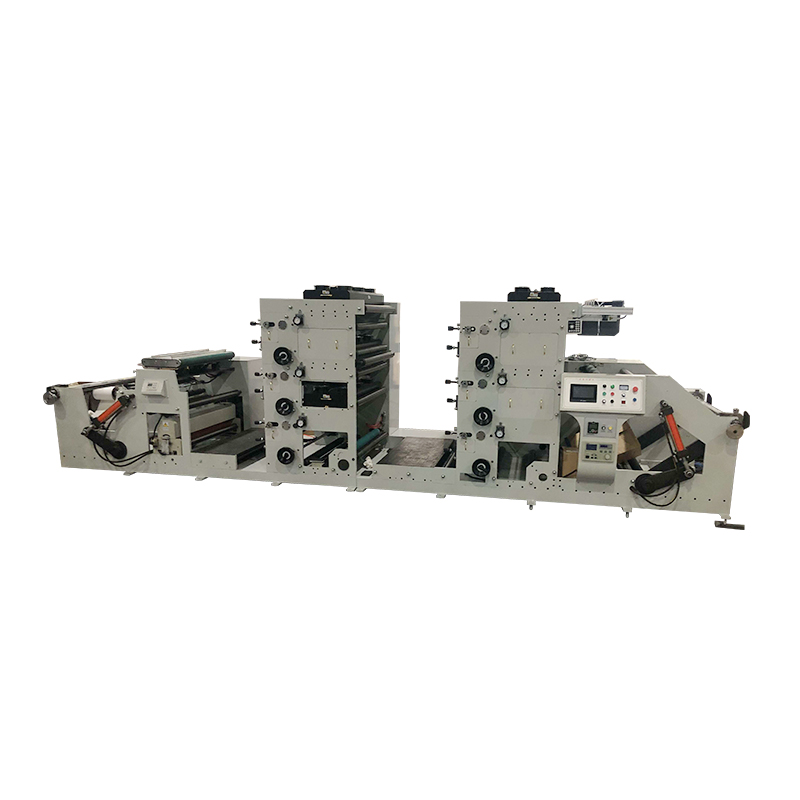

Model:Cheap PriceList for Plate Manufacturing Machine - 6 Color Flexo Printing Machine HEY130-6-860 &#...

Technical Parameter Printing speed 55m-60m/min Printing color 6 colors Print max width 850mm Unwind roll width 860mm Unwind roll diameter 1300mm Rewind roll max diameter... -

Model:

Model:Professional China Plastic Glass Making Machine Price - Factory China Disposable Food Container ...

We normally believe that one’s character decides products’ quality, the details decides products’ high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for... -

Model:

Model:New Fashion Design for Paper Plate Making Machine Low Price - 18-35OZ Paper Bucket Making Machin...

Paper cup bottom sealing by Leister CERAMIC hot air system, BRAND BANKO. It is easy to make cups of different size by changing moulds. Cup side sealing by ultrasonic. Double PE coating paper cups ... -

Model:

Model:High Performance Paper Plate Machine For Sale - Paper Cup Sleeve Machine HEY145 – GTMSMART

Paper Cup & Bowl Sleeve Machine Technical Parameter Model Ultrasonic Paper Cup Sleeve Machine Paper Bowl Size 6 oz-16 oz (mold exchangeable) height up to 125 mm Raw Materia... -

Model:

Model:Ordinary Discount Food Container Making Machine - Single Station Automatic Thermoforming machine...

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) wit...