Gtmsmart Best price china good quality large vacuum forming machine thermoformer machine manufacturers

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for best price good quality vacuum forming machine, china vacuum forming machine manufacturers, Thermoformer Machine, Thermoforming Machine Automatic Tray, Thermoforming Machine Manufacturer, Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures.

Application

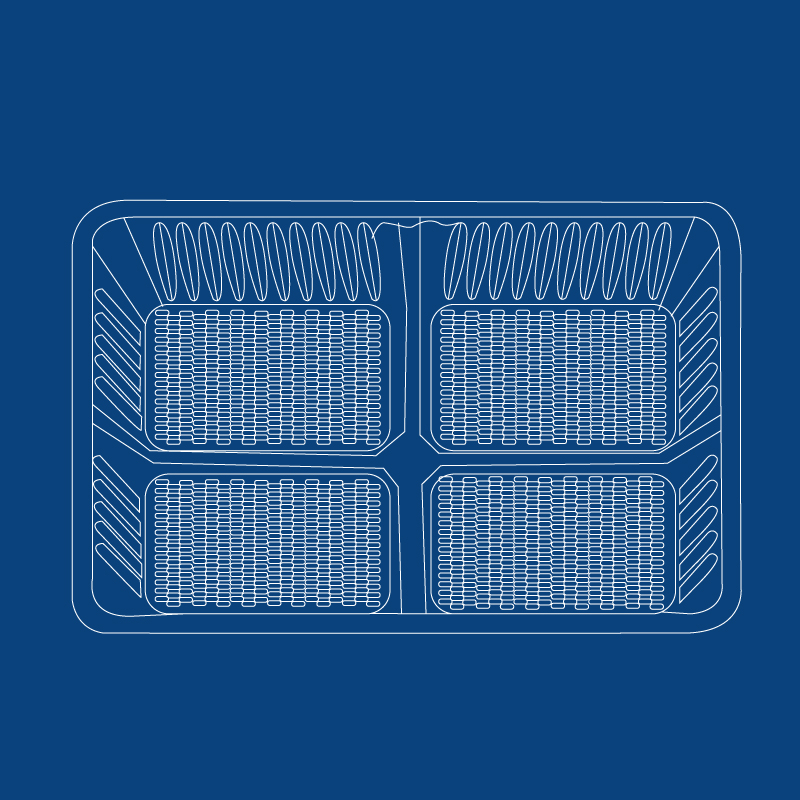

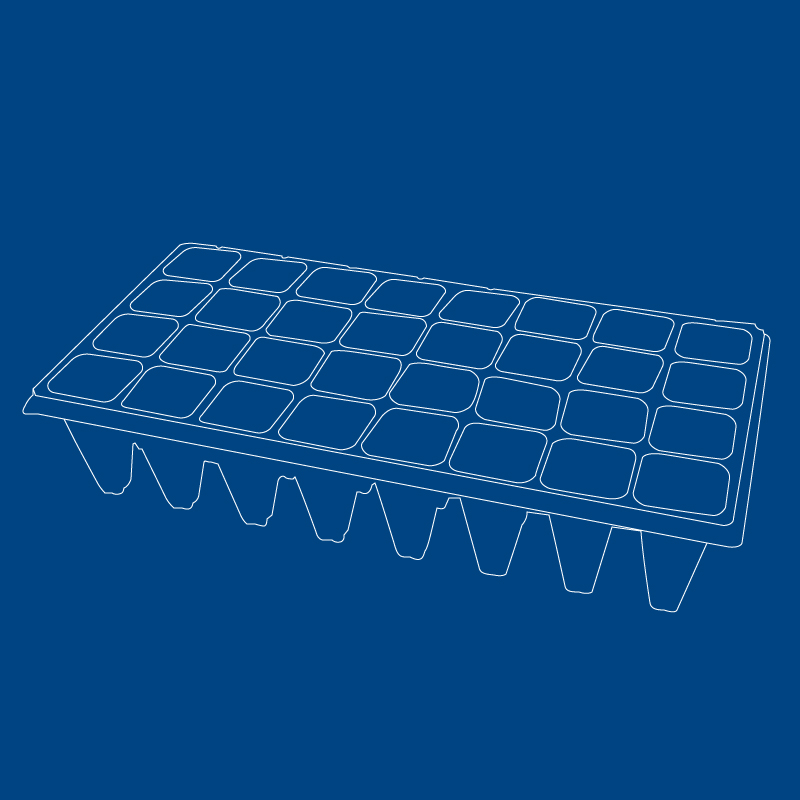

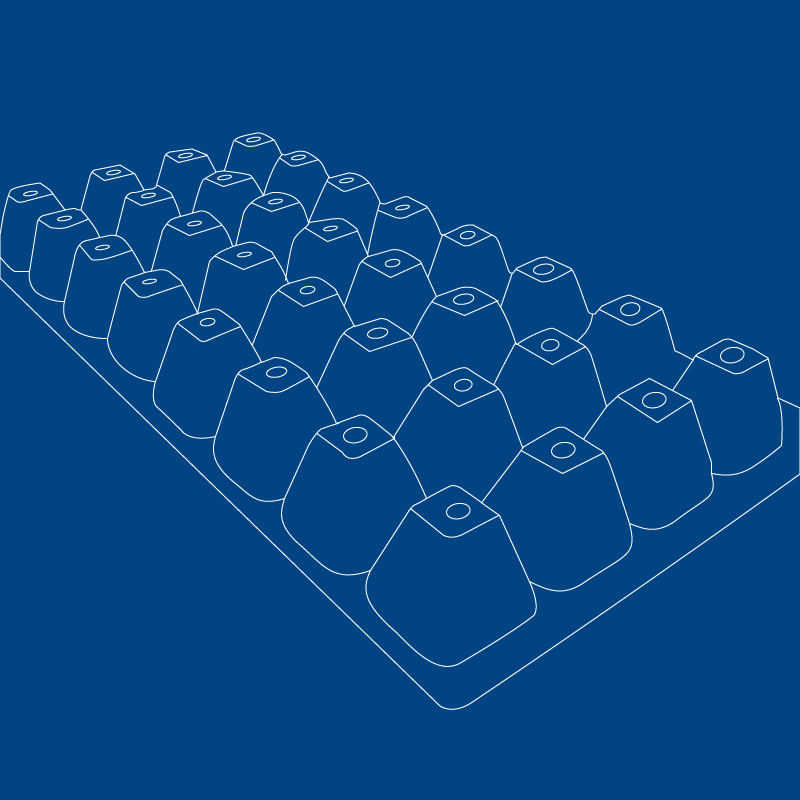

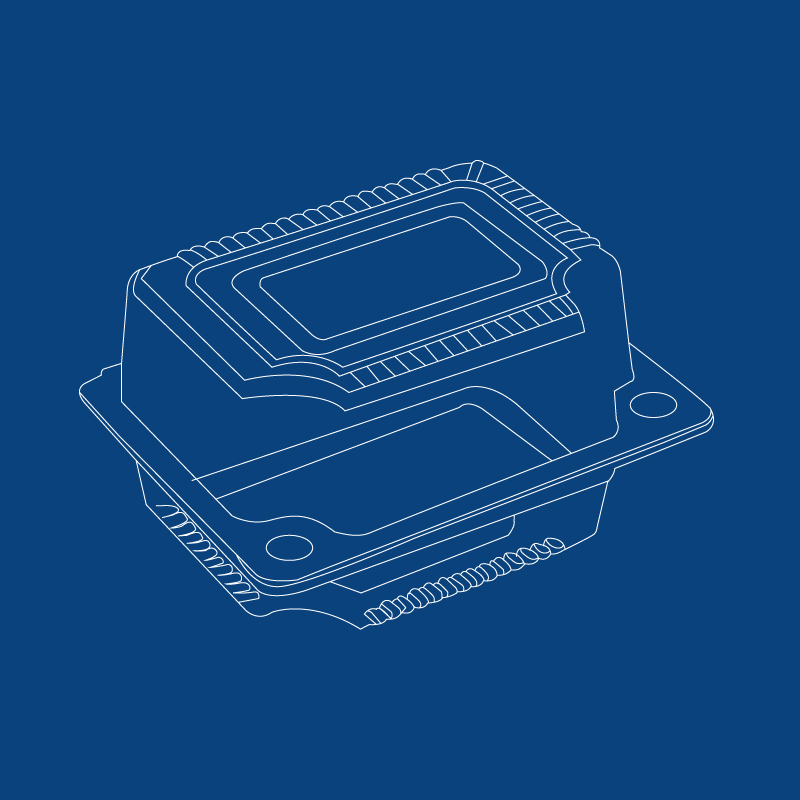

This Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets.

Three Stations Negative Pressure Forming Machine Features

1.Mechanical, pneumatic, electrical integration. Each action program is controlled by PLC. Touching screen operation is simple and convenient.

2.Vacuum Forming In-mould Cutting.

3.Up and down moulds forming type.

4.Servo feeding, length step less adjusting, high speed accurately and stablity.

5.Negative Pressure Forming Machine Up and down heater with two phases heating.

6.Electric heating furnace temperature control system adopts full computer intelligent automatic compensation control, partition control using digital input interface one by one, has the high precision fine-tuning, uniform temperature, heating up fast (only 3 minutes from 0-400 degrees), stability (not influenced by external voltage, temperature fluctuations no more than 1 degree), low energy consumption (energy saving about 15%), the furnace plate advantages for long life.

7.Forming and cutting station with open and close servo motor control, products with automatic tally output.

8.Products can be choosing by you to down stacking type,Or the manipulator is taken in the mold.

9.Plastic Thermoforming Machine with product information and data memory function.

10.Feeding caterpillar width can be synchronization automatic or discretely electric adjusting.

11.Heater automatic shift out device.

12.Mechanical loading device, reduce workers labor strength.

Negative Pressure Forming Machine Technical Parameter

| Forming Area Max(mm) | 720*760 |

| Forming Area Min(mm) | 420*350 |

| Max. Forming Depth(mm) | 100 |

| Sheet Thickness(mm) | 0.2-1.0 |

| Sheet Width(mm) | 450-750 |

| Applicable Material | PS, PP, PET, PVC, ABS |

| Accuracy of Sheet Transport(mm) | 0.15 |

| Working Cycle Max (cycle/min) | 25 |

| Stroke of upper mold(mm) | 200 |

| Stroke of lower mold(mm) | 200 |

| Length of upper heater(mm) | 1270 |

| Length of lower heater (mm) | 1270 |

|

Mold closing force Max(T) |

50 |

| Max. Capacity of Vacumm Pump | 100m³/h |

| Power Supply | 380V/50Hz 3 phrase 4 wire |

| Machine Dimension(mm) | 6880*2100*2460 |

| Weight of Whole Machine (T) | 9 |

| Heating Power(kw) | 78 |

| Power of Driving Motor(kw) | 22 |

| Total Power(kw) | 120 |

Gtmsmart Best price china good quality large vacuum forming machine thermoformer machine manufacturers. Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001, Sincerely look ahead to serving you.

Send your message to us:

Products Recommended

More +-

Model: HEY01

Model: HEY01PLC Pressure Thermoforming Machine With Three Stations HEY01

PLC Pressure Thermoforming Machine With Three Stations HEY01 Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit cont... -

Model: HEY06

Model: HEY06Negative Pressure Forming Machine For Seedling Tray HEY06

Negative Pressure Forming Machine For Seedling Tray Application This Negative Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( seeding tray, frui... -

Model: HEY05

Model: HEY05Plastic Vacuum Forming Machine HEY05

Vacuum Thermoforming Machine Description Vacuum forming, also known as thermoforming, vacuum pressure forming or vacuum molding, is a procedure in which a sheet of heated plastic material is... -

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, ... -

Model: HEY03

Model: HEY03Single Station Automatic Thermoforming machine HEY03

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc...