Factory source Thermoforming Cup Making Machine - Three Stations Negative Pressure Forming Machine HEY06 – GTMSMART

Factory source Thermoforming Cup Making Machine - Three Stations Negative Pressure Forming Machine HEY06 – GTMSMART Detail:

Application

Automatic Vacuum Forming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets.

Vacuum Forming Machine Features

1.Mechanical, pneumatic, electrical integration. Each action program is controlled by PLC. Touching screen operation is simple and convenient.

2.Vacuum Forming In-mould Cutting.

3.Up and down moulds forming type.

4.Servo feeding, length step less adjusting, high speed accurately and stablity.

5.Blister Vacuum Forming Machine Up and down heater with two phases heating.

6.Electric heating furnace temperature control system adopts full computer intelligent automatic compensation control, partition control using digital input interface one by one, has the high precision fine-tuning, uniform temperature, heating up fast (only 3 minutes from 0-400 degrees), stability (not influenced by external voltage, temperature fluctuations no more than 1 degree), low energy consumption (energy saving about 15%), the furnace plate advantages for long life.

7.Forming and cutting station with open and close servo motor control, products with automatic tally output.

8.Products can be choosing by you to down stacking type,Or the manipulator is taken in the mold.

9.Plastic vacuum forming machine with product information and data memory function.

10.Feeding caterpillar width can be synchronization automatic or discretely electric adjusting.

11.Heater automatic shift out device.

12.Mechanical loading device, reduce workers labor strength.

Vacuum Forming Machine Technical Parameter

| Forming Area | 850x780mm |

| Max.Forming Depth | 150mm |

| Sheet thickness | 0.2-1.5mm |

| Work Efficiency | Max. 30 cycles/ Min |

| Air Pressure | 0.9mpa |

| Power Consumption | 50-70kw/h |

| Max. Sheet Width | 760mm |

| Suited Material | PP, PS, PET, PVC |

| Total Max. Power | 110 |

| Overall size(LxWxH)mm | 10040x2600x3200 |

| Total Weight (T) | 7 |

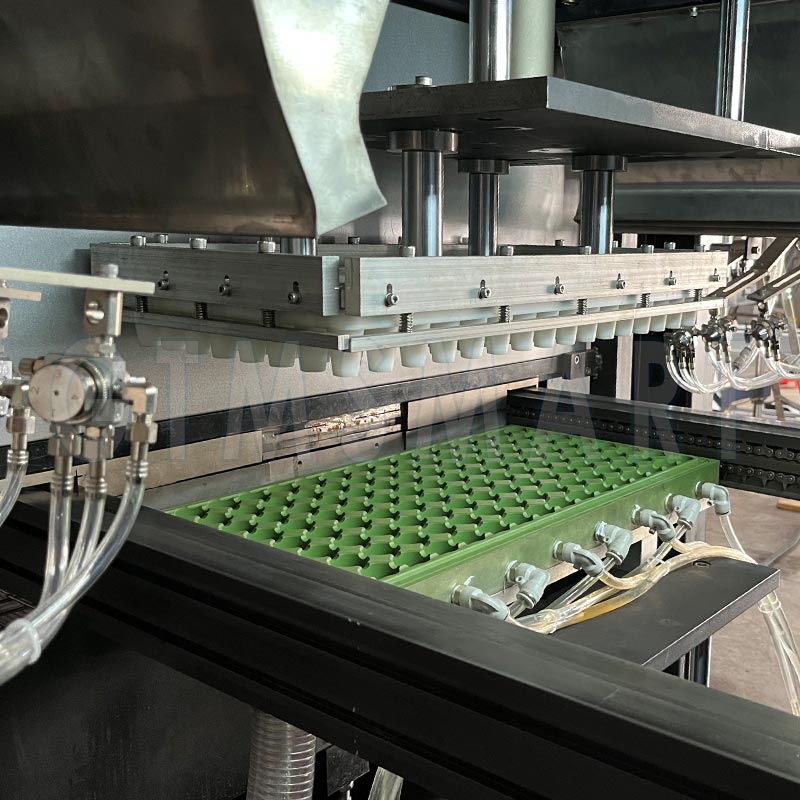

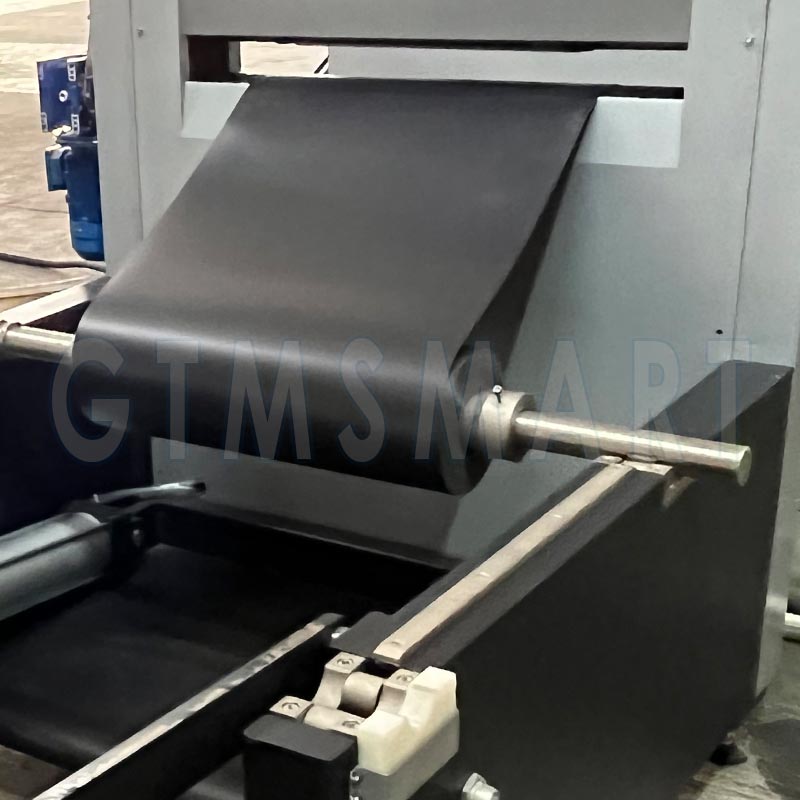

Product detail pictures:

Related Product Guide:

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Factory source Thermoforming Cup Making Machine - Three Stations Negative Pressure Forming Machine HEY06 – GTMSMART , The product will supply to all over the world, such as: Durban , Slovenia , Italy , The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.

Send your message to us:

Products Recommended

More +-

Model:

Model:Best Price on Thermoform Machines - PLC Pressure Thermoforming Machine With Three Stations HEY01...

Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) with ther... -

Model:

Model:China Cheap price Paper Glass Making Machine - Biodegradable PLA Disposable Plastic Cup Making M...

Application Biodegradable cup making machine mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers, etc) with thermoplastic sheets, such as PP, P... -

Model:

Model:OEM Manufacturer Paper Cup Machine Cost - Full Servo Plastic Cup Making Machine HEY12 – GT...

cup making machine Application The cup making machine is Mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers, etc) with thermoplastic sheets, s... -

Model:

Model:Best quality Paper Cup Forming Machine - Biodegradable PLA Disposable Plastic Cup Making Machine...

Application Biodegradable cup making machine mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers, etc) with thermoplastic sheets, such as PP, P... -

Model:

Model:Professional China Thermoformers - Three Stations Negative Pressure Forming Machine HEY06 –...

Application Automatic Vacuum Forming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets. Vacuum Forming ... -

Model:

Model:Factory Price For Automatic Thermoforming Machine Hs Code - Four Stations Large PP Plastic Therm...

Product Introduction Four Stations Large PP Plastic Thermoforming Machine is forming, cutting and stacking in one line. It is completely driven by servo motor, stable operation, low noise, high eff...