Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, belief the very first and management the advanced" for blister packing machine suppliers, buy vacuum former machine, Pvc Blister Forming Machine, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We now have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our goods are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

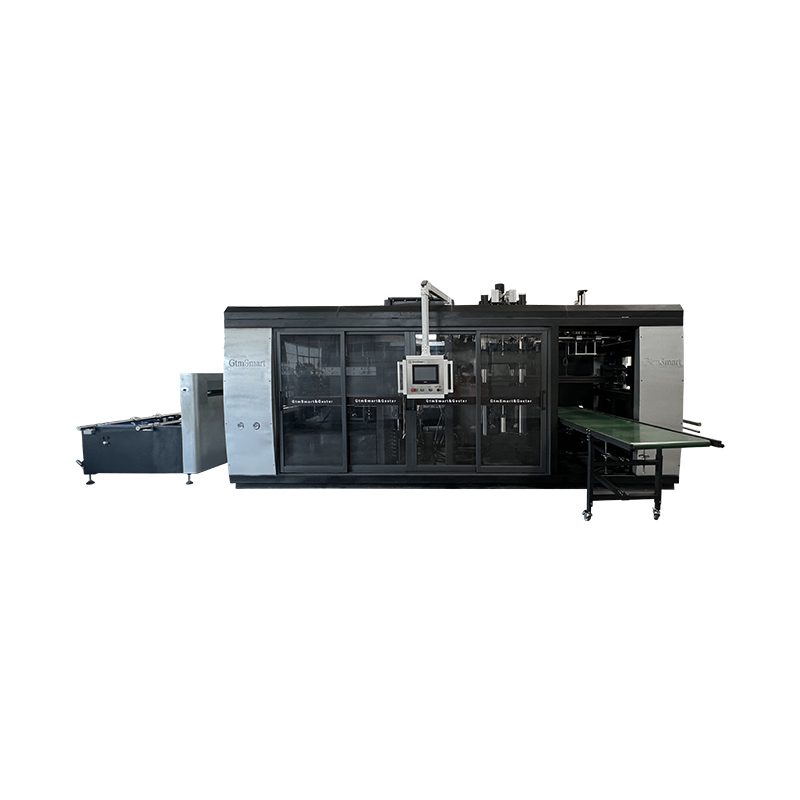

Vacuum Thermoforming Machine Description

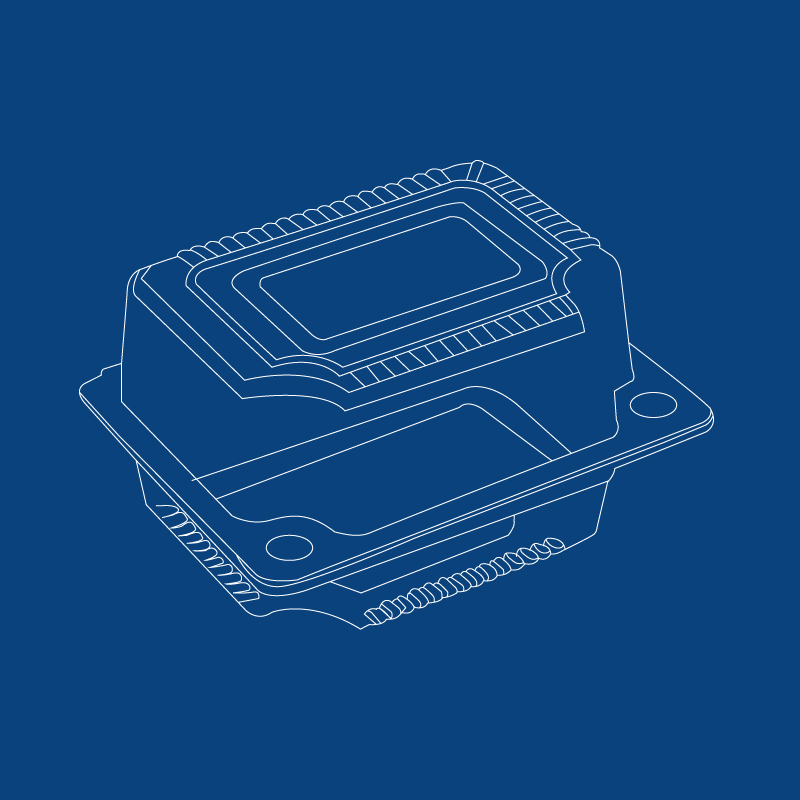

Vacuum forming, also known as thermoforming, vacuum pressure forming or vacuum molding, is a procedure in which a sheet of heated plastic material is shaped a certain way.

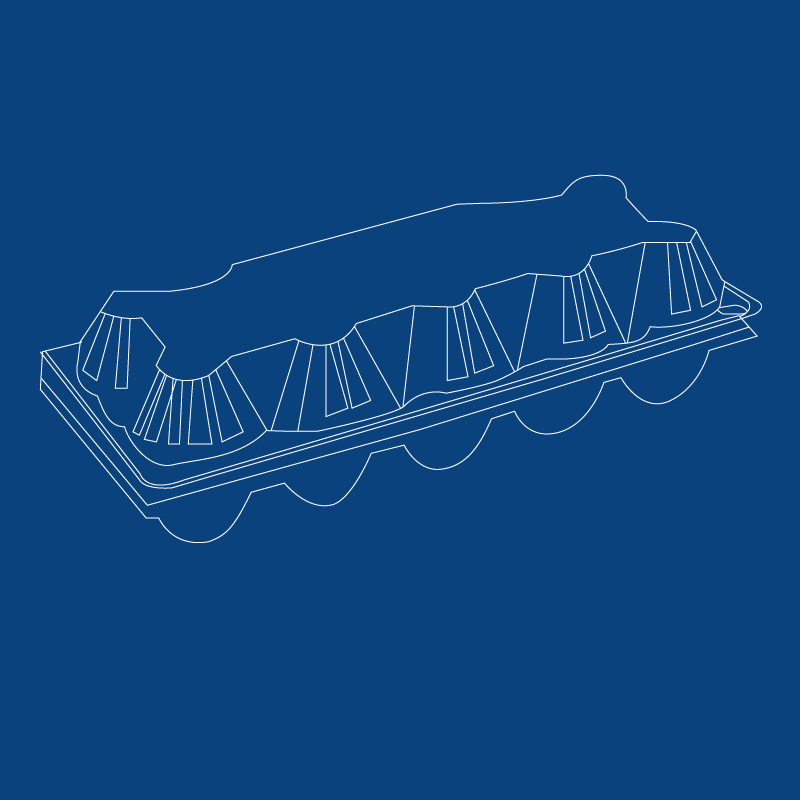

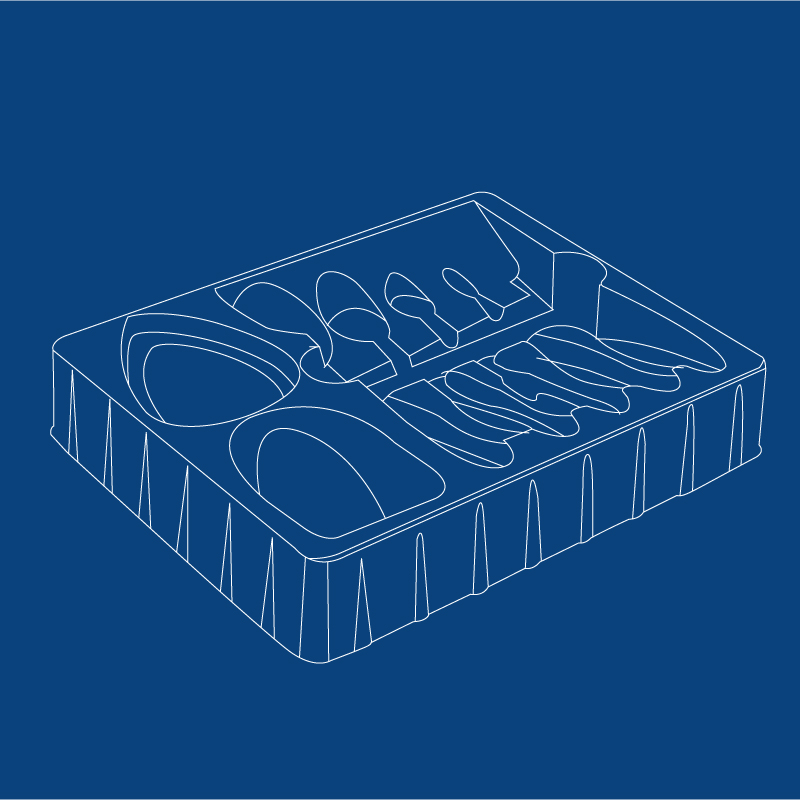

Automatic Plastic vacuum Forming Machine: Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets, such as PET, PS, PVC etc.

Product Advantages

- This Vacuum Forming Machine Utilizes PLC control system, servo drives upper and lower mould plates, and servo feeding, which would be more stable and precision.

-

Human-computer interface with high definition contact-screen, which can monitor the operation situation of all parameter setting.

- The Plastic vacuum forming machine Applied self-diagnosis function, which can real-time display breakdown information, easy to operate and maintenance.

- The pvc vacuum forming machine can store several product parameters, and the debugging is quick when producing different products.

Automatic Vacuum Forming Machine Specifications

| Model |

HEY05B |

| Working Station |

Forming, Stacking |

| Applicable Material |

PS, PET, PVC, ABS |

| Max. Forming Area (mm2) |

1350*760 |

| Min. Forming Area (mm2) |

700*460 |

| Max. Formed Depth (mm) | 130 |

| Sheet Width (mm) | 490~790 |

| Sheet Thickness (mm) | 0.2~1.2 |

| Accuracy of Sheet Transport (mm) | 0.15 |

| Max. Working Cycle (cycles/minute) | 30 |

| Stroke of Upper/Lower Mold (mm) | 350 |

| Length of Upper/Lower Heater (mm) | 1500 |

| Max. Capacity of Vacuum Pump (m3/h) | 200 |

| Power Supply | 380V/50Hz 3 Phrase 4 Wire |

| Dimension (mm) | 4160*1800*2945 |

| Weight (T) | 4 |

| Heating Power(kw) | 86 |

| Power of Vacuum Pump (kw) | 4.5 |

| Power of Driving Motor (kw) | 4.5 |

| Power of Sheet Motor (kw) | 4.5 |

| Total Power(kw) | 120 |

Send your message to us:

Products Recommended

More +-

Model: HEY06

Model: HEY06Three Stations Negative Pressure Forming Machine HEY06

Three Stations Negative Pressure Forming Machine HEY06 Application This Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package ... -

Model: HEY01

Model: HEY01PLC Pressure Thermoforming Machine With Three Stations HEY01

PLC Pressure Thermoforming Machine With Three Stations HEY01 Product Introduction This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit cont... -

Model: HEY12

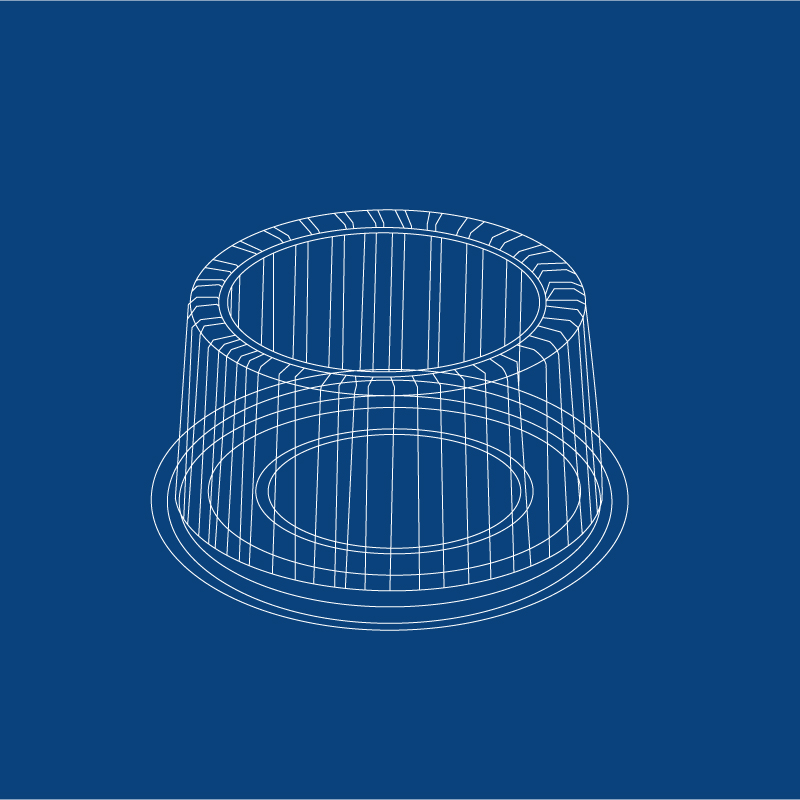

Model: HEY12Biodegradable PLA Disposable Plastic Cup Making Machine

PLA Biodegradable Disposable Plastic Cup Making Machine Application Biodegradable cup making machine mainly for the production of variety plastic containers ( jelly cups, drink cups, package conta... -

Model:

Model:Automatic Disposable Plastic Glass Making Machine Cup Thermoforming Machine

Cup Making Machine Introduction Plastic glass cup making machine is suitable for molding PP, PET, PS, PLA and other plastic sheets to produce various packaging products such as boxes, plates, ... -

Model:

Model:ECO Friendly Compostable Biodegradable Burger Packaging Boxes

Industry-specific attributes Industrial Use Food packaging Material PLA biodegradable Other attributes Place of Origin Quanzhou, China Size Customized Size Custom Or... -

Model:

Model:Eco Friendly PLA Biodegradable Disposable Round Plates

Product parameters Product Name Biodegradable Plate Material type PLA Dimension Customized Size Color White Usage Home, Hotel,Restaurant ect. MOQ 5000 pcs Product Descriptio... -

Model:

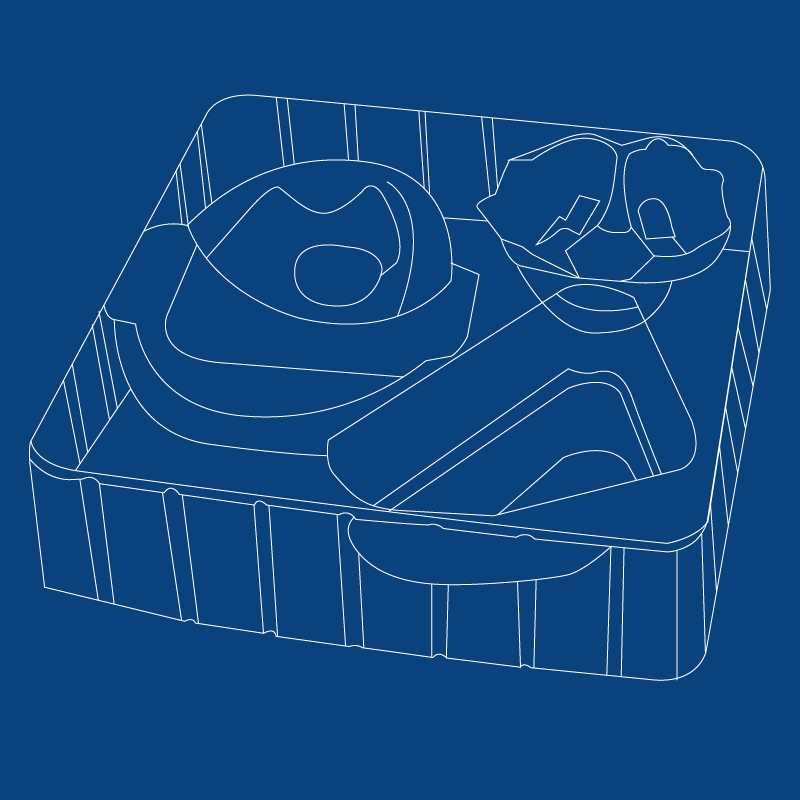

Model:PLA Biodegradable Bento Lunch Box Takeaway Plastic Round Food Container Bowl With Lid

Product Paramenters Products Name Lunch Box Bowl Material PLA Corn starch Shape Round Size 11.5cm*11.5cm*4.5cm Capacity 750ML MOQ 5000 pcs Product Description Size... -

Model:

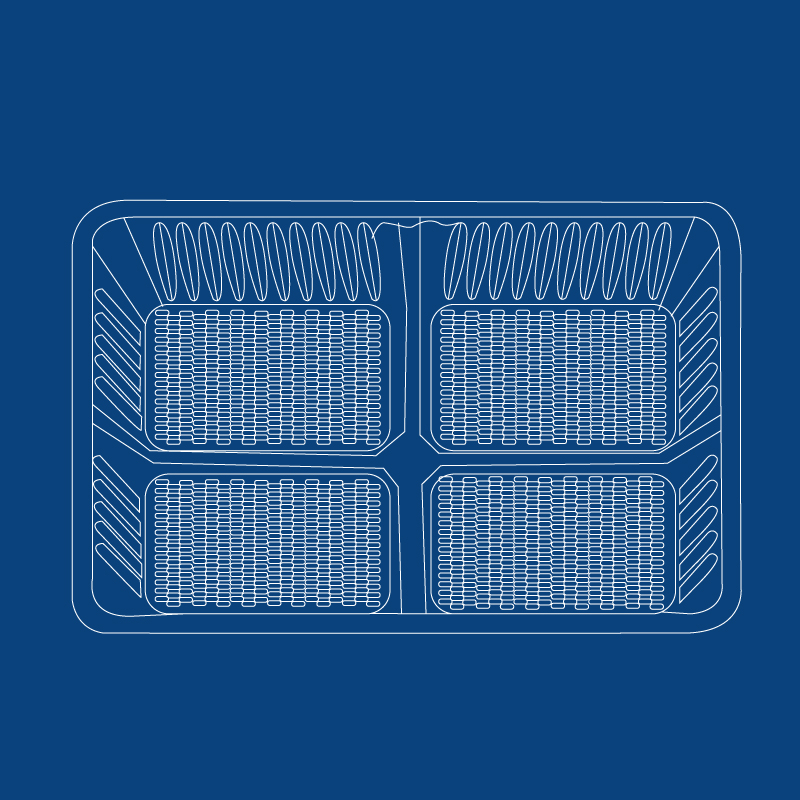

Model:PLA Biodegradable Disposable 4 Compartment Takeaway Lunch Box With Lid

Product Paramenters Products Name 4 compartment lunch box Material PLA Corn starch Size 23.5cm*19cm*4.5cm Capacity 850ML MOQ 5000 pcs -

Model:

Model:PLA Biodegradable Plastic Disposable Takeaway Square Lunch Box

Product Paramenters Products Name Lunch box Material PLA Size 17.5cm*12cm*4cm Capacity 500ML MOQ 5000 pcs Product description -

Model:

Model:PLA Corn Starch Biodegradable Compostable Disposable Cups

Product parameters Product Name biodegradable cup Capacity 8oz/9oz/10oz/12oz/24oz Materials PLA Color Red and white, Clear MOQ 5000 psc Feature Eco-Friendly Usage Cold drink/ Coffee/... -

Model:

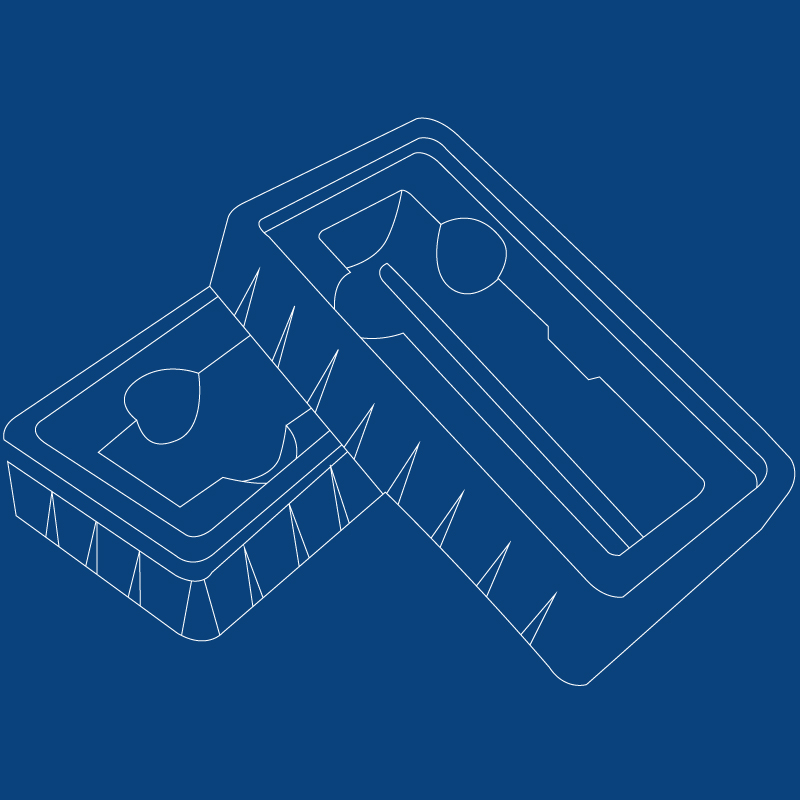

Model:PLA Biodegradable Knives Eco Friendly Disposable Cutlery

Product parameters Product Name PLA Knife Material PLA Size 7in, 18in MOQ 10000 pcs Advantages Factory direct sale, eco friendly, compostable Product Description ...