Machine Description

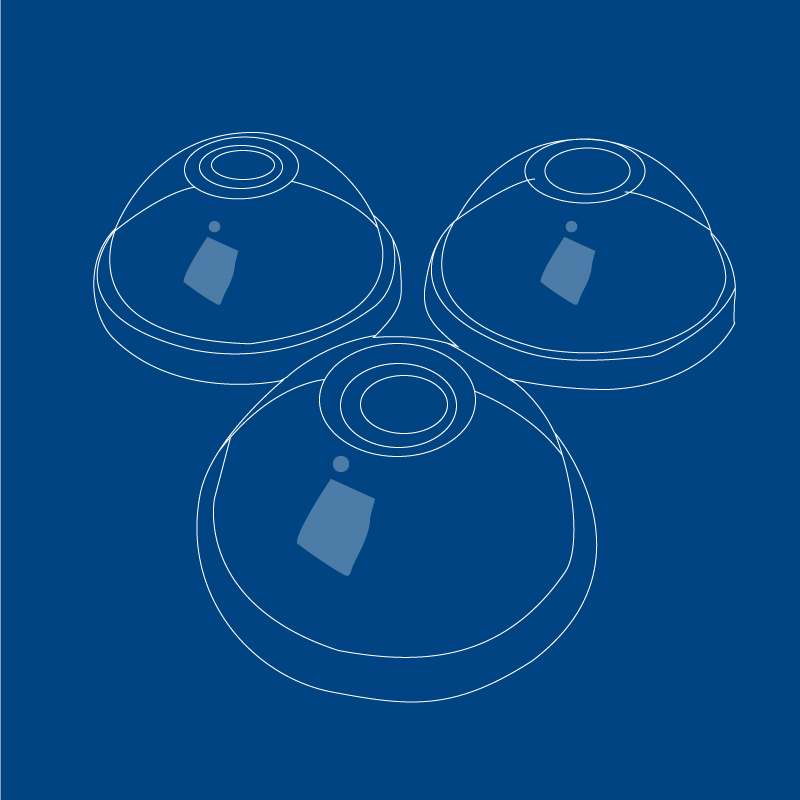

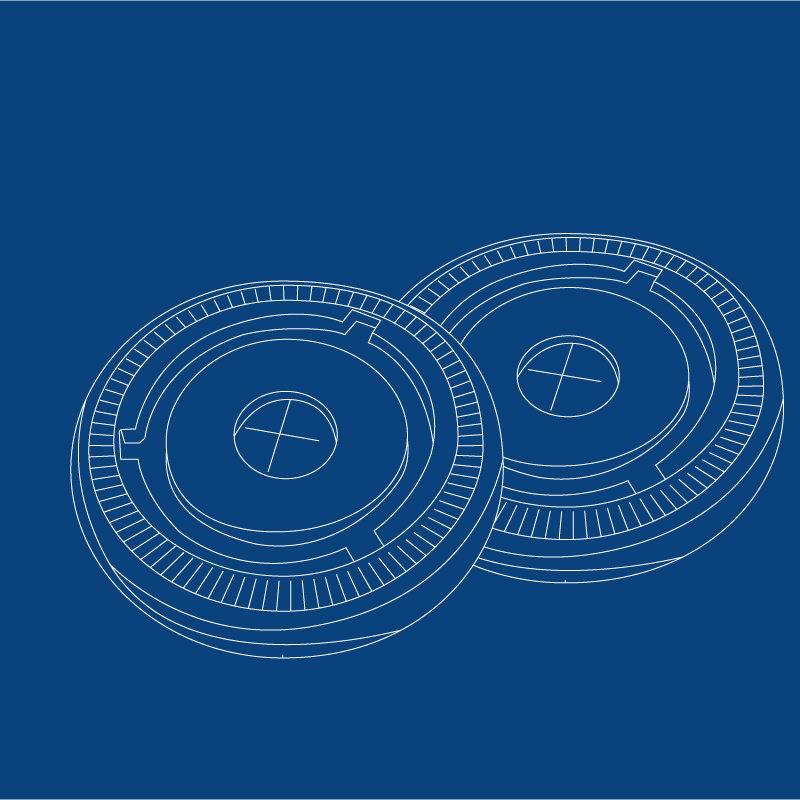

Automatic Lids Thermoforming Machine are developed by our research and development department, according to the demand of packing market. Absorbing the advantages of aluminum-plastic blister packaging machine and plastic molding machine, Machine adopts automatic forming, punching and cutting as the special properties of product requires of the users. With advanced technology, safe and simple operation, avoiding the consumption of labor caused by manual punching and the pollution caused by the employees during work, guarantee the quality of products. The thermoforming machine equipped with panels heating, low power consumption, small external footprint, economical and practical. So the machine is widely used in manufacturing lids, covers, trays, plates, boxes.

Applications:

PVC, PET, PS, as raw materials, changing the mold at one machine to manufacturing lids, covers, trays, plates, boxes, food and medical trays, etc.

Technical Parameters

| Model | HEY04A |

| Punch Speed | 15-35 times/minute |

| Max. Forming Size | 470*290mm |

| Max. Forming Depth | 47mm |

| Raw Material | PET, PS, PVC |

| Max. Sheet Width | 500mm |

| Sheet Thickness | 0.15-0.7mm |

| Sheet Inner Roll Diameter | 75mm |

| Stoke | 60-300mm |

| Compressed Air(Air Compressor) | 0.6-0.8Mpa, around 0.3cbm/minute |

| Mold Cooling(Chiller) | 20℃, 60L/H, tap water / recycle water |

| Total Power | 11.5Kw |

| Main Motor Power | 2.2Kw |

| Overall Dimension | 3500*1000*1800mm |

| Weight | 2400 KG |

Performance Characteristics

- The lid forming machine realizes automatic control through the combination of programmable controller (PLC), man-machine interface, encoder, photoelectric system, etc., and the operation is simple and intuitive.

- The Cup Lid Thermoforming Machine: transmission adopts the reducer and the main rotation connection. Forming, punching, pulling, and punching stations are on the same axis to ensure operational synchronization (reduced transmission error).

- Automatic lifting and loading material system is safe and labor-saving, plate type upper and lower preheating device temperature control system is stable to ensure uniform heating, various molding methods to ensure the appearance of the product is beautiful, servo traction are intelligent and reliable, punching and punching knife are durable and no burr, mold replacement is simple, main engine adopts the frequency conversion speed regulation to run smoothly.

- The lid making machine whole body is welded by steel box, the structure is firm and no deformation, the bracket and the box are under pressure molding, high density and no air holes, and the appearance is evenly wrapped with stainless steel, which is beautiful and easy to maintain.

- The roller servo traction system makes the machine run more stable and reliable, increases the traction length and can directly set the traction length and traction speed in the man-machine interface through PLC programming, which increases the forming area and expands the applicable range of the machine.

Send your message to us:

Products Recommended

More +-

Model: HEY04B

Model: HEY04BLid Making Machine HEY04B

Lid Making Machine Introduction The lid making machine includes forming, punching & cutting, automatic process operation, advanced technology, safe and easy operation, to avoid the labor c... -

Model:

Model:Biodegradable PLA Lids

MOQ: 20GP PLA Biodegradable Factory direct sale Environmentally friendly Lids sold separately. Customizable Compostable PLA cup lids fits on 9, 12, 16, 20 and 24 oz cups. PLA bio-plastic made fro... -

Model: HEY12

Model: HEY12Biodegradable PLA Disposable Plastic Cup Making Machine

PLA Biodegradable Disposable Plastic Cup Making Machine Application Biodegradable cup making machine mainly for the production of variety plastic containers ( jelly cups, drink cups, package conta... -

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, ... -

Model: GTM03

Model: GTM03One Station Forming Machine with Punching Machine GTM03

Forming Machine Main Technical Data Cycle speed maximum (with good CN mold) Forming and cutting production cycle of up to 30 cycles/min. Single forming production cycle of up to 35 cycles/min. ... -

Model: HEY06

Model: HEY06Negative Pressure Forming Machine For Seedling Tray HEY06

Negative Pressure Forming Machine For Seedling Tray Application This Negative Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( seeding tray, frui... -

Model: HEY05

Model: HEY05Plastic Vacuum Forming Machine HEY05

Vacuum Thermoforming Machine Description Vacuum forming, also known as thermoforming, vacuum pressure forming or vacuum molding, is a procedure in which a sheet of heated plastic material is... -

Model: GTM110C-2

Model: GTM110C-2High Speed Paper Cup Glass Making Machine GTM110C-2

Key Specification High speed paper cup glass making machine is the latest invented and upgraded model of our company. It adopt the advantages of domestic and abroad technology, which is suitable to...