18 Years Factory Pvc Tray Making Machine - PLC Pressure Thermoforming Machine With Three Stations HEY01 – GTMSMART

18 Years Factory Pvc Tray Making Machine - PLC Pressure Thermoforming Machine With Three Stations HEY01 – GTMSMART Detail:

Product Introduction

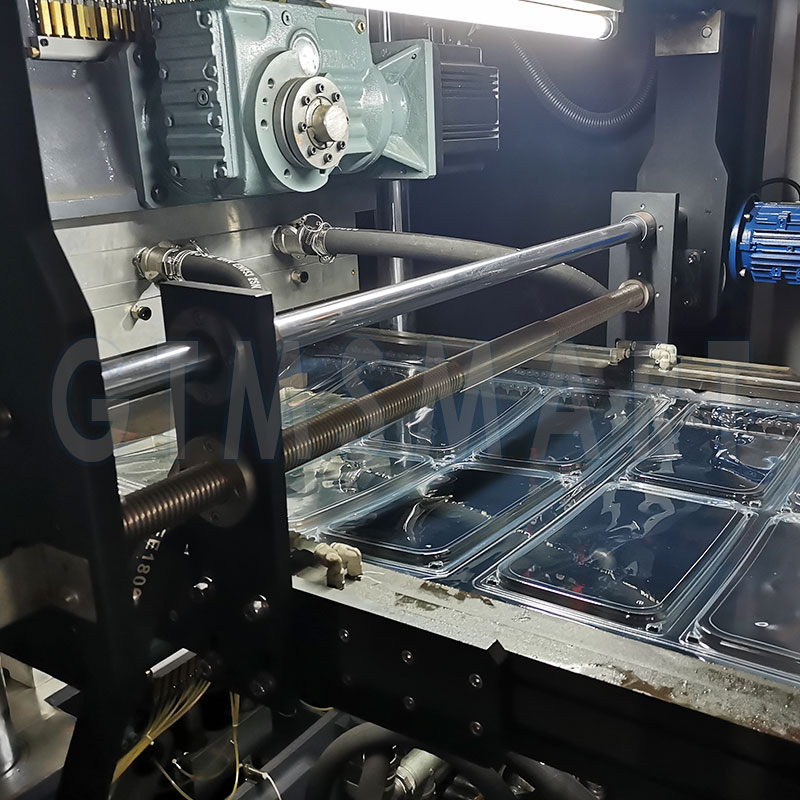

This Pressure Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) with thermoplastic sheets, such as PP,APET, PS, PVC, EPS, OPS, PEEK, PLA, CPET,etc.

Feature

- Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy.

- Pressure And/Or Vacuum forming.

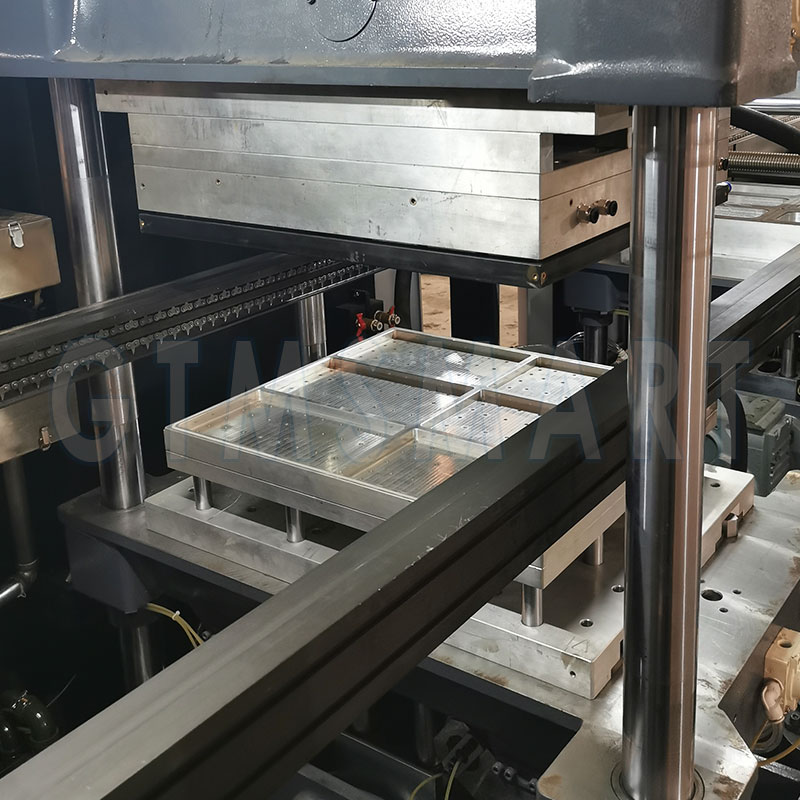

- Thermoforming Machine: Upper and down mould forming.

- Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

- Upper & lower heater, four sections heating.

- Heater with intellectual temperature control system,which has high precision, uniform temperature, won’t be effected by outer voltage.Low power consumption (energy saving 15%), ensure the longer service life of heating furnace.

- Forming and cutting unit mold open and close controlled by servo motor, products automatically count.

- Products be stacked downward.

- Plastic Thermoforming Machine: data memorization function.

- Feeding width can be synchronously or independently adjusted in electrical way.

- Heater will automatically push-out when the sheet is over.

- Auto roll sheet loading, reduce the working load.

Plastic Thermoforming Machine Key Specification

| Model |

HEY01-6040 |

HEY01-6850 |

HEY01-7561 |

||

| Max.Forming Area (mm2) |

600×400 |

680×500 |

750×610 |

||

| 3 Stations |

Forming, Cutting, Stacking |

||||

| Sheet Width (mm) | 350-720 | ||||

| Sheet Thickness (mm) | 0.2-1.5 | ||||

| Max. Dia. Of Sheet Roll (mm) | 800 | ||||

| Forming Mould Stroke(mm) | Upper Mould 150, Down Mould 150 | ||||

| Power Consumption | 60-70KW/H | ||||

| Forming Mould Width (mm) | 350-680 | ||||

| Max. Formed Depth (mm) | 100 | ||||

| Cutting Mould Stroke(mm) | Upper Mould 150,Down Mould 150 | ||||

| Max. Cutting Area (mm2) |

600×400 |

680×500 |

750×610 |

||

| Cutting Force (ton) | 40 | ||||

| Dry Speed (cycle/min) | Max 30 | ||||

| Product Cooling Method | By Water Cooling | ||||

| Vacuum Pump | UniverstarXD100 | ||||

| Power Supply | 3 phase 4 line 380V50Hz | ||||

| Max. Heating Power | 121.6 | ||||

| Max. Power of Whole Machine (kw) | 150 | ||||

| Max. Machine Dimension(L*W*H) (mm) | 11150×2300×2700 | ||||

| Weight of Whole Machine ( T ) | ≈11 | ||||

Brand of Main Components

| PLC | Taiwan Delta |

| Touch Screen Monitor (10 inch) | Taiwan Delta |

| Feeding Servo Motor (3kw) | Taiwan Delta |

| Forming Down Mould Servo Motor (3kw) | Taiwan Delta |

| Forming Upper Mould Servo Motor (3kw) | Taiwan Delta |

| Cutting Down Mould Servo Motor (3Kw) | Taiwan Delta |

| Cutting Upper Mould Servo Motor (5.5Kw) | Taiwan Delta |

| Stacking Servo Motor(1.5Kw) | Taiwan Delta |

| Heater (192 pcs) | TRIMBLE |

| AC Contactor | French Schneider |

| Thermo Relay | Schneider |

| Intermediate Relay | Japan Omron |

| Air Switch | South Korea LS |

| Pneumatic Component | MAC. AirTAC/ ZHICHENG |

| Cylinder | China ZHICHENG |

20 years experience

GTMSMART Machinery Co., Ltd. is an innovative technology enterprise integrating technology, industry and trade. It mainly develops and produces various types of high-precision automatic production equipment.

The newly developed GTM series of fully automatic air pressing molding production line includes: feeding unit, pre-heating unit, forming unit, vertical blanking unit, stack unit, scrap winding unit, punching cutting and stacking three-in-one horizontal blanking unit, online labeling unit, etc., which can be combined with flexible production line according to different production requirements of customers.

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for 18 Years Factory Pvc Tray Making Machine - PLC Pressure Thermoforming Machine With Three Stations HEY01 – GTMSMART , The product will supply to all over the world, such as: Cancun , Houston , USA , Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our merchandise and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

Send your message to us:

Products Recommended

More +-

Model:

factory low price Pvc Box Making Machine - Single Station Automatic Thermoforming machine HEY03 ...

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) wit... -

Model:

Model:Fixed Competitive Price Thermo Plastic Forming Machine - Three Stations Negative Pressure Formin...

Application Automatic Vacuum Forming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, package containers, etc) with thermoplastic sheets. Vacuum Forming ... -

Model:

Model:Professional China Pla Corn Starch Biodegradable Tray Thermoforming Machine - Factory China Disp...

We normally believe that one’s character decides products’ quality, the details decides products’ high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for... -

Model:

Model:Manufacturing Companies for Plastic Lid Thermoforming Machine - Single Station Automatic Thermof...

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) wit... -

Model:

Model:2022 wholesale price Plastic Disposable Cup Making Machine - New Delivery for China High Speed F...

We’ve been also concentrating on bettering the things management and QC method in order that we could continue to keep terrific benefit inside the fiercely-competitive company for New Deliver... -

Model:

Model:Factory Cheap Hot Thermoforming Machine Working Principle - Single Station Automatic Thermoformi...

Product Introduction Single Station Automatic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc) wit...